Besfit ? China's high-end intelligent automotive equipment brand

Shanghai Suteng Machinery Equipment Co., Ltd. was founded in 2003, relying on independent core technology and system integration advantages, to provide customers with high stability, high time, high precision flexible products, to become specialized in automotive automation production 4.0, intelligent logistics system conveying equipment, integrated installation and debugging and system simulation solutions leader.

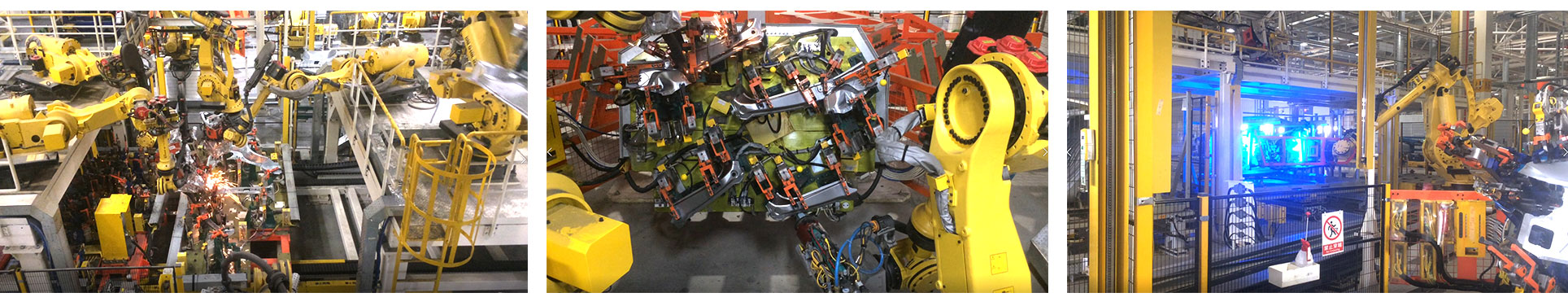

For the automotive industry, digital transformation is no longer a choice question, but a must for long-term development. The company adopts specialized, intelligent, digital and flexible manufacturing processes and technologies to provide strong support for the global strategy of intelligent manufacturing in the automotive industry.

The company has comprehensively benchmarking international advanced technology and production procedures and standards, constantly developing advanced equipment and technology for intelligent manufacturing, and is committed to producing safer and smarter products to enhance product competitiveness.

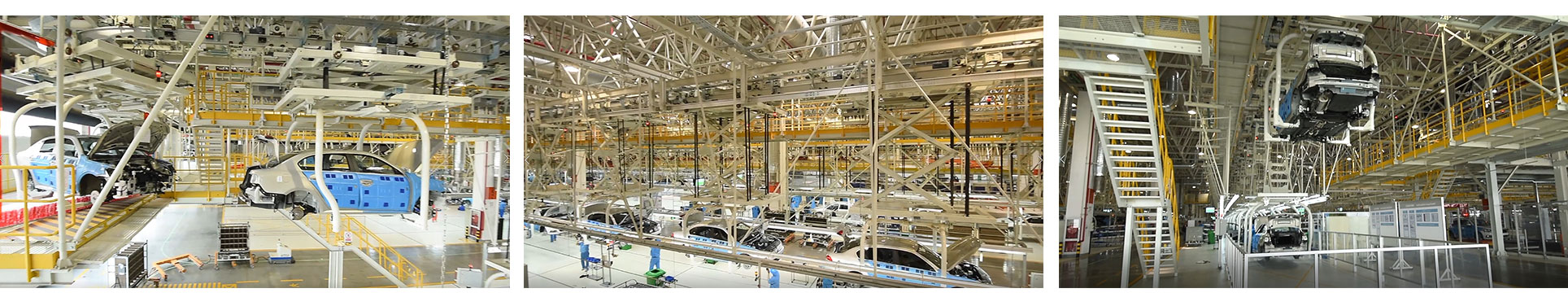

Independent research and development of high-speed drawbar lifting roller conveyor, has its high tempo, high precision characteristics, to fill the gaps in the domestic, become the new benchmark of the industry, the product and has been used in SAIC Volkswagen, SAIC GM, SAIC Chase, Volkswagen Anhui, FAW-Volkswagen, Chinese Express, ideal automobile and other domestic and foreign auto factories.

Independent research and development of the same type of eccentric lifting rolling machine, screw lifting rolling machine, is also widely used in joint venture brands and independent brands and other automobile factories.

The successfully developed and applied separate EMS system abandons the shackles of traditional EMS conveying system, realizes high stock and high flexibility, and provides customers with more flexible, more intelligent and lower cost solutions. The system has been applied and put into operation successively in FAW-VOLKSWAGEN Foshan EMB factory, SAIC Volkswagen Anting MEB Factory and Volkswagen Anhui Hefei factory, and has been unanimously recognized by customers.

The independently developed lifting spadder system adopts PCM and DKZ control mode, which makes the control more simple and reliable, and has European safety certification, successfully replacing foreign imported brands.

In order to adapt to the industry trend of heavier, larger and faster beat of new energy vehicles, the independently developed heavy-duty friction line conveying system has been successfully applied to SAIC GM, Ideal and other automobile manufacturers.

We independently developed and successfully applied the first heavy-duty 3 ton friction line conveying system in China.

copyright ? BESFIT (Shanghai) Intelligent Equipment Co., Ltd Besfit Admin